After I wrote my previous blog on upsizing patterns for feltmaking, I thought I should write about how I figure out the shrinkage percentages to use when making the patterns bigger. First of all, the samples I maker are really important to this process. Not only do they help me figure out what colors and textures I want to use in the garment, but they also help me figure out the shrinkage.

My biggest word of advice for sampling is to make it

large enough to get an accurate measurement. I make a minimum of a 20 inch (50 cm) square

sample using the types of textures, cloth and fiber I want to use in the final

felt garment. For me, if I make anything smaller, the shrinkage

is much more than if it is a larger piece. In the past when I did this, I

ended up with something that was way too big. I don't always lay the fiber both

directions in my garments, so I need to make my sample with the single layer.

Also, I have found that if I am adding cloth to the surface and other surface

embellishments, the shrinkage isn't as much as when I am just using a thin base

cloth and the fiber layer. When I've done a garment that has both flat areas

and large areas of texture, I make two samples, one just flat and one with the

textures I think I'm going to use in the garment. Then I estimate how much

textured area I'm going to have and how much flat area. If I'm just going to do

a small amount of surface texture, I will use the shrinkage from the flat

sample and it won't be affected too much. On the other hand, if I'm going to do

a lot of surface texture with very little flat area, I use the shrinkage from

the surface textured sample. But, if I am going to use about half flat and half

with surface texture, I average the two different samples. Side Note: I am

usually making a "sandwiched" felt textile in my garments. I put down

a base of silk gauze, cover that with a thin, single layer of wool fiber and

then put on the surface embellishments such as pleated or gathered bits of

fabric, ribbon, yarns, pre-felts, fiber locks, etc.

There are many different versions of the formulas for figuring out the felt's shrinkage. People seem to have a hundred different ways to get to the same place. My husband is a mathematician, so here are the formulas he helped me come up with:

| ||

| Formulas Needed for Making Your Pattern for a Felted Garment |

So let's say I want to make a sample which is going to be simple, with no texture- just the ground cloth and the fiber on top of it. The sample will start out at 20 inches (50 cm) square but I will only lay the fiber in the vertical direction on top of the silk gauze ground. After felting, the sample in the vertical direction is 13.5 inches (34.29 cm.) In the opposite direction it's 17.5 inches (44.45 cm.) Since the fiber was only laid in one direction, it is not unusual that the shrinkages in the two directions would be so different.

Figuring the Vertical Shrinkage Using my Husband's Formula:

A= 20 inches

B= 13.5 inches

A-B = 6.5

Divided by A = .325

Times 100 = 32.5% (Which I would round up to 33%- I try to round up so there's a little extra for the "just in case" factor.)

Figuring the Horizontal Shrinkage:

A= 20 inches

B= 17.5 inches

A-B= 2.5

Divided by A=.125

Times 100= 12.5% (Rounded up to 13%)

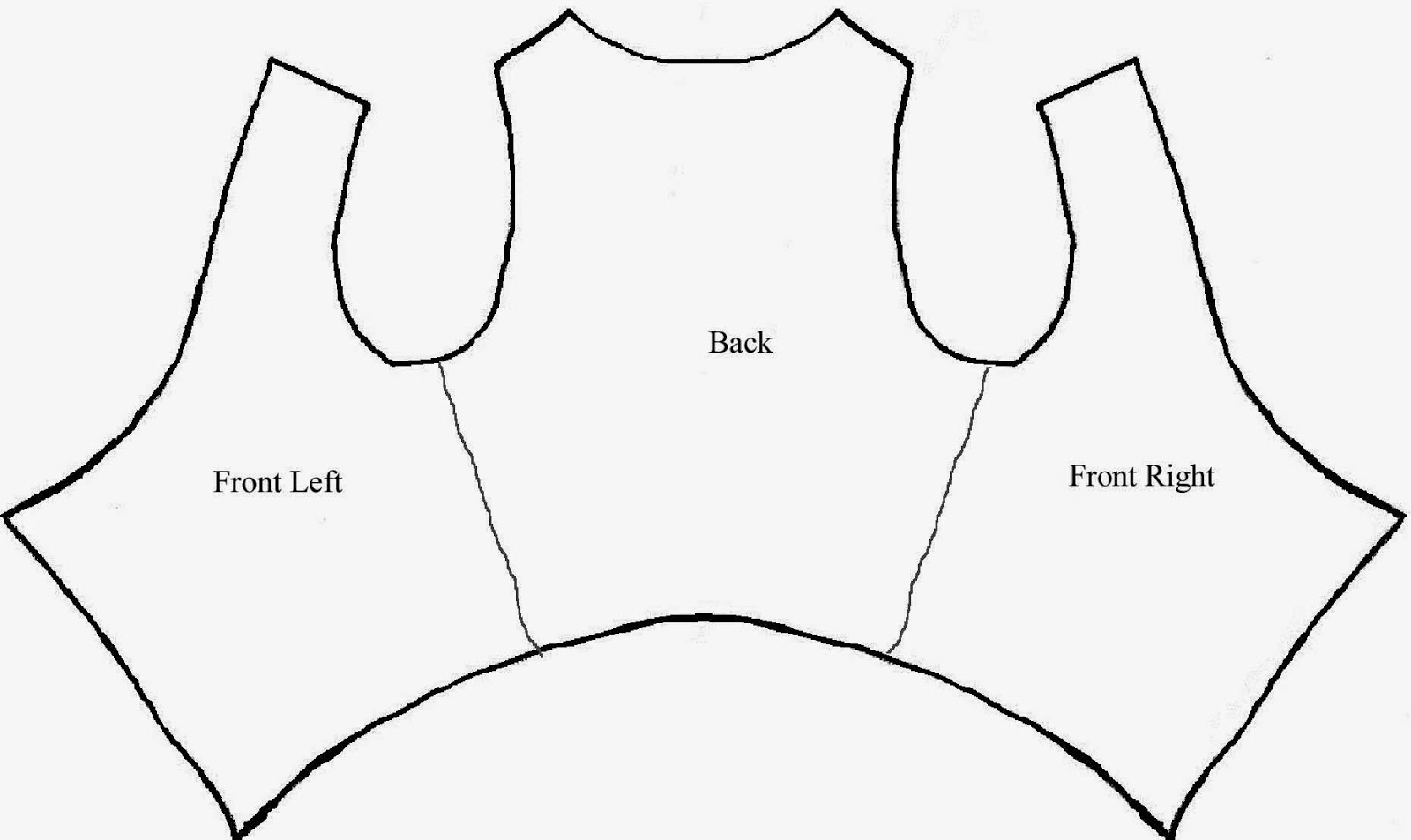

Now you have to figure out the size you will need to make your template so that the felt made from it will shrink down to the size you want. As stated in my previous blog entry, I have already made a paper pattern either from an existing garment or from a sewing pattern. If I am doing a seamless garment, I will usually work with just the back back piece as I've mentioned in the previous post. I measure the widest and tallest part of the pattern. I use these measurements to figure out how much bigger the template pattern needs to be before shrinkage.

Figuring the Pattern Size Before Shrinkage

Vertical Size

C= .33

D (Desired Finished Vertical Dimension of Garment Back) = 28 inches

D divided by 1-C

28 divided by .67= 41.79 inches (rounded up to 42 inches)

So the beginning vertical size of the template is 42 inches. Yes, this seems large, but that is why you need so much table space to make a garment!

Horizontal Size

C= .13

D (Desired Finished Horizontal Dimension of Garment Back) = 22 inches

D divided by 1-C

22 divided by .87= 25.287 inches (rounded up to 26 inches)

The horizontal part of the template is only 26 inches wide because there is so much less shrinkage in this direction. Remember, the fiber is being laid out vertically.

The original paper pattern would have to be increased in the height and width to allow for the shrinkage calculated above. To do this, I usually take the desired size and subtract it from the size before shrinkage.

For the Vertical calculations above this would be 42 inches minus 28 inches. Which would be 14 inches. I would slice my pattern up and separate it, spreading the 14 inches I need to add in small increments across the whole thing. Since 14 divides nicely by 7, I would probably make 7 slices and spread each one 2 inches apart to take up the 14 inches.

The Horizontal calculations would be 26 - 22, which would be 4 inches. To spread this out, I would probably make 4 slices and spread each one apart by 1 inch.

I try to be very careful in the shoulders, armholes and neck line to remember to include enough slices that they will not be too small, but also to not get them too big. This can be tricky, so I often try to allow for the possibility that they won't fit exactly. If they are a little too large, you can thread a strong, thin cord through the middle of the felt in that area and tug it to slightly gather up the excess. If there are any wrinkles, these can sometimes be smoothed away with a steam iron. If the area is too small, you might be able to apply steam (such as from a tea kettle) and stretch out the area while it is still damp and hot from the steam.

.jpg)